promex CYRUS

INLINE SURFACE INSPECTION FOR ALUMINUM PROFILES

promex CYRUS

INLINE SURFACE INSPECTION FOR ALUMINUM PROFILES

HIGHLY ACCURATE DETECTION OF SURFACE DEFECTS BASED ON ARTIFICIAL INTELLIGENCE

HIGHLY ACCURATE DETECTION OF SURFACE DEFECTS BASED ON ARTIFICIAL INTELLIGENCE

AI makes the difference. Yield Optimization in an intelligent way.

Bildtitel

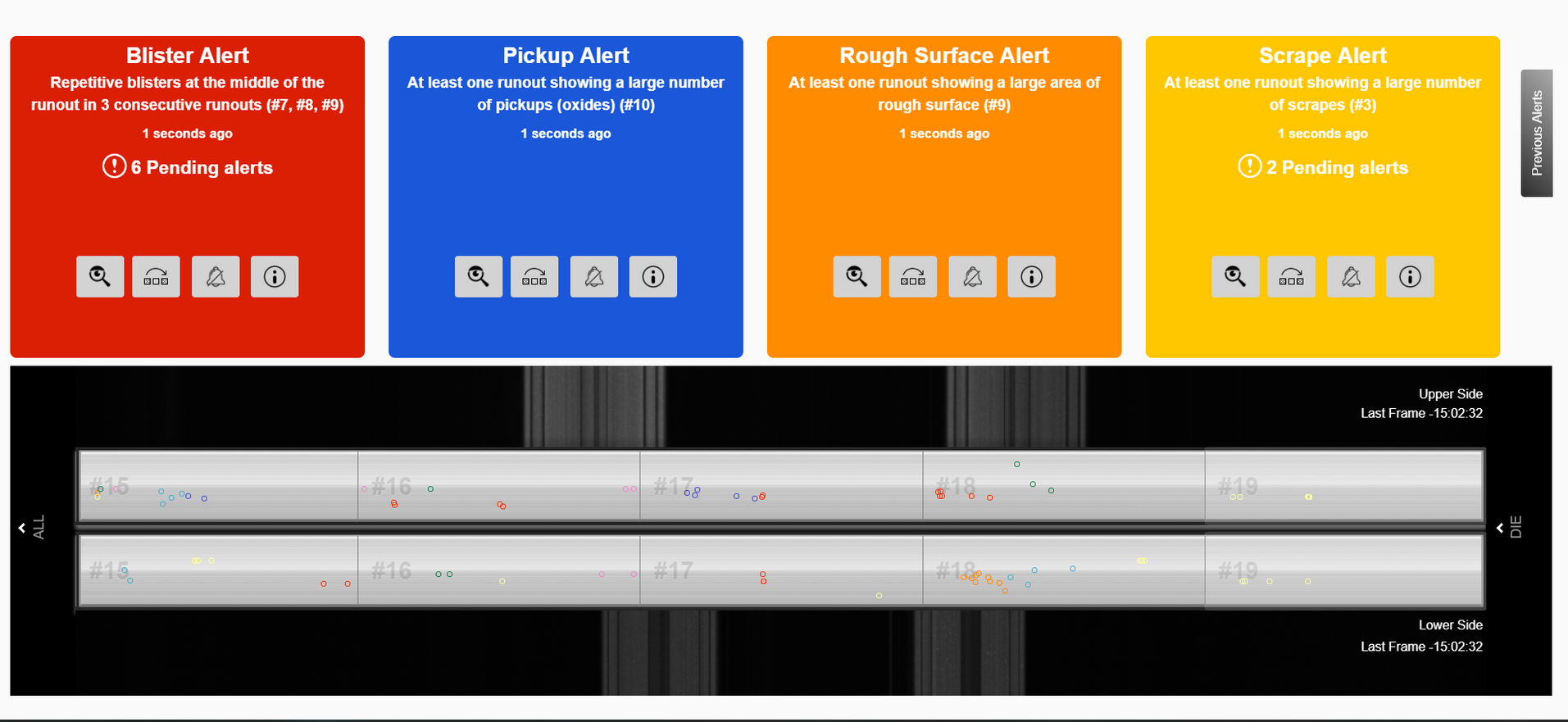

BLASEN

Button

Bildtitel

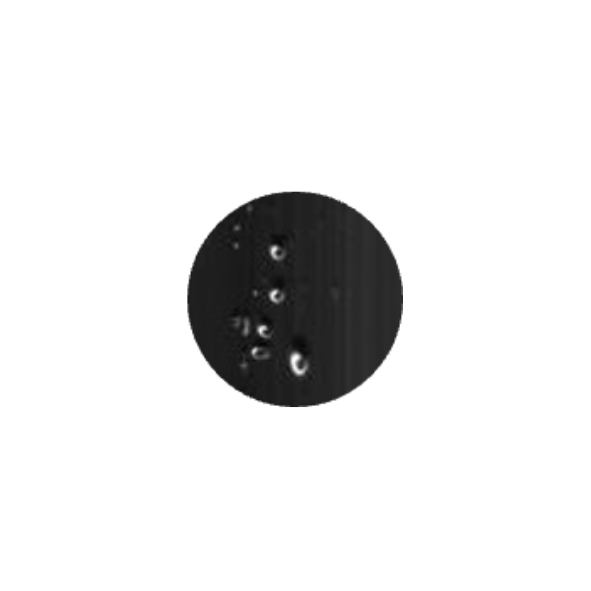

KRATZER

Button

Bildtitel

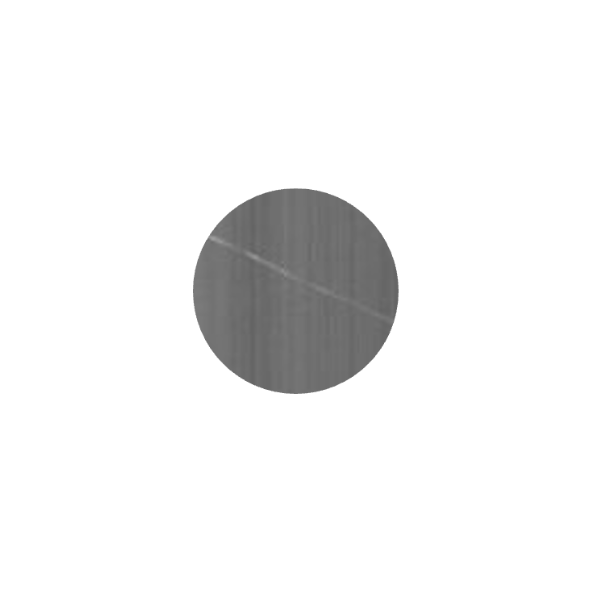

SCRAPE/TEARING

Button

Bildtitel

PICKUPS

Button

Bildtitel

STOP-MARKS

Button

Bildtitel

SNAP-MARKS

Button

Bildtitel

RAUHE OBERFLÄCHE

Button

Bildtitel

TWISTS

Button

AI makes the difference. Yield Optimization in an intelligent way.

AI makes the difference.

Yield Optimization in an intelligent way.

Bildtitel

BLISTERS

Button

Bildtitel

SCRATCHES

Button

Bildtitel

SCRAPES/TEARINGS

Button

Bildtitel

PICKUPS

Button

Bildtitel

STOP-MARKS

Button

Bildtitel

SNAP-MARKS

Button

Bildtitel

ROUGH SURFACE

Button

Bildtitel

TWISTS

Button

BLISTERS

SCRATCHES

SCRAPES/TEARINGS

PICKUPS

STOP-MARKS

SNAP-MARKS

ROUGH SURFACE

TWISTS

BLISTERS

STOP-MARKS

SNAP-MARKS

ROUGH SURFACE

SCRATCHES

PICKUPS

TWISTS

SCRAPES/TEARINGS

KEY FEATURES

>

INDIVIDUAL IMPLEMENTATION THROUGH MODULAR CONCEPT

>

INSTALLATION DIRECTLY AT THE PRESS

> DIE AGNOSTIC DETECTION

>

SOFTWARE BASED ON ARTIFICIAL INTELLIGENCE

>

100 % DEFECT CLASSIFICATION IN REAL-TIME

>

SMART ALERTING FOR PRESS OPERATORS

>

REMOTE MONITORING OF THE PRODUCTION THROUGH CLOUD-

>

BASED AI DATA MANAGEMENT SYSTEM

> REPORTS AND STATISTICAL EVALUATIONS OF THE SURFACE

>

INSPECTION

BENEFITS

KEY FEATURES

>

INDIVIDUAL IMPLEMENTATION THROUGH

> MODULAR CONCEPT

>

INSTALLATION DIRECTLY AT THE PRESS

>

DIE AGNOSTIC DETECTION

>

SOFTWARE BASED ON ARTIFICIAL

>

INTELLIGENCE

>

100 % DEFECT CLASSIFICATION IN REAL-TIME

>

SMART ALERTING FOR PRESS OPERATORS

>

REMOTE MONITORING OF THE PRODUCTION

>

THROUGH CLOUD-BASED AI DATA

> MANAGEMENT SYSTEM

> REPORTS AND STATISTICAL EVALUATIONS OF

>

THE SURFACE INSPECTION

BENEFITS

> REAL-TIME DETECTION AT AN EARLY STAGE OF

> PRODUCTION

> EARLY INITIATION OF PRODUCTION

> OPTIMIZATION ACTIVITIES

>

PREVENTION OF UNNECESSARY DOWNSTREAM

> PROCESSING

> AUTONOMOUS DEVELOPMENT AND

> IMPROVEMENT OF THE

>

SOFTWARE THROUGH THE USE OF ARTIFICIAL

> INTELLIGENCE

>

REDUCTION OF PRODUCTION, PROCESSING

> AND RECYCLING COSTS

>

REDUCTION OF POWER CONSUMPTION AND

> CO2 EMISSIONS

> HIGH POTENTIAL FOR MONETARY AND

> MATERIAL SAVINGS

>

REAL-TIME DETECTION AT AN EARLY STAGE OF PRODUCTION

>

EARLY INITIATION OF PRODUCTION OPTIMIZATION ACTIVITIES

>

PREVENTION OF UNNECESSARY DOWNSTREAM PROCESSING

>

AUTONOMOUS DEVELOPMENT AND IMPROVEMENT OF THE

>

SOFTWARE THROUGH THE USE OF ARTIFICIAL INTELLIGENCE

>

REDUCTION OF PRODUCTION, PROCESSING AND RECYCLING

>

COSTS

>

REDUCTION OF POWER CONSUMPTION AND CO2 EMISSIONS

> VALUABLE FINANCIAL AND MATERIAL SAVINGS

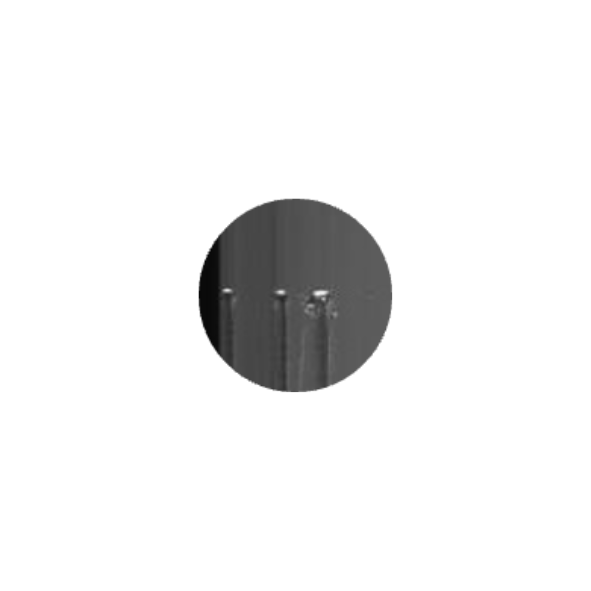

SMART ALERTING

SMART ALERTING FOR PRESS OPERATORS

The press operator gets real-time alters through an intuitive user interface for recurring defects that indicate a deterioration in surface quality and scrap generation. The meaningful alerts instructs the operator to initiate targeted corrective action at an early stage.

SMART ALERTING

SMART ALERTING FOR PRESS OPERATORS

The press operator gets real-time alters through an intuitive user interface for recurring defects that indicate a deterioration in surface quality and scrap generation. The meaningful alerts instructs the operator to initiate targeted corrective action at an early stage.

SMART ALERTING

SMART ALERTING FOR PRESS OPERATORS

The press operator gets real-time alters through an intuitive user interface for recurring defects that indicate a deterioration in surface quality and scrap generation. The meaningful alerts instructs the operator to initiate targeted corrective action at an early stage.

AI DATA MANAGEMENT SYSTEM

INTELLIGENT REMOTE MONITORING AND STATISTICS FOR PRODUCTION OPTIMIZATION

A holistic cloud-based solution that stores the surface inspection data of each production line in a single or multiple extrusion plants, providing multiple benefits for various departments:

Plant management:

Remote monitoring of the production in real-time

Quality management:

Defect map for each extrusion and online tools to assess artificial intelligence performance

Extrusion management:

Early detection of scrap and powerful tool for production optimization

Maintenance management:

Surface history log for each die to initiate proactive repairs

IT-Management:

Extensive data pool for exploitation in value-added business intelligence reports

Sales Management:

Valuable insights into product quality to adjust strategies accordingly

AI DATA MANAGEMENT SYSTEM

INTELLIGENT REMOTE MONITORING AND STATISTICS FOR PRODUCTION OPTIMIZATION

A holistic cloud-based solution that stores the surface inspection data of each production line in a single or multiple extrusion plants, providing multiple benefits for various departments:

Plant management:

Remote monitoring of the production in real-time

Quality management:

Defect map for each extrusion and online tools to assess artificial intelligence performance

Extrusion management:

Early detection of scrap and powerful tool for production optimization

Maintenance management:

Surface history log for each die to initiate proactive repairs

IT-Management:

Extensive data pool for exploitation in value-added business intelligence reports

Sales Management:

Valuable insights into product quality to adjust strategies accordingly

AI DATA MANAGEMENT SYSTEM

INTELLIGENT REMOTE MONITORING AND STATISTICS FOR PRODUCTION OPTIMIZATION

A holistic cloud-based solution that stores the surface inspection data of each production line in a single or multiple extrusion plants, providing multiple benefits for various departments:

Plant management:

Remote monitoring of the production in real-time

Quality management:

Defect map for each extrusion and online tools to assess artificial intelligence performance

Extrusion management:

Early detection of scrap and powerful tool for production optimization

Maintenance management:

Surface history log for each die to initiate proactive repairs

IT-Management:

Extensive data pool for exploitation in value-added business intelligence reports

Sales Management:

Valuable insights into product quality to adjust strategies accordingly

"The reliable detection of surface defects, inline at the press mouth, was a vision many years ago to improve the surface quality and to reduce scrap. CYRUS made this possible and it is a step into a new decade for the aluminium extrusion world. For a continuous improvement we need measured responses, which are not only dimensions and mechanical properties, but also the surface quality from order to order. We are now capable to compare the impact of different press parameters and die designs to maximize surface quality and minimize the surface quality related scrap. But next to this continuous improvement potential, CYRUS provides us with an intelligent alarm system warning the press operator immediately about the loss of quality, like f.e. Tearing, Blisters or Pick-ups. So, the decisions are taken faster at the press. Due to the use of a camera underneath the initial table our press operators are informed about any defect they hardly can detect by their eyes in a second. We are very happy with the CYRUS quality of detection and we do not want to miss this system anymore.”

Dr. Raphael Mertens

Extrusion Process Manager Hydro Nenzing

MashIt

"The reliable detection of surface defects, inline at the press mouth, was a vision many years ago to improve the surface quality and to reduce scrap. CYRUS made this possible and it is a step into a new decade for the aluminium extrusion world. For a continuous improvement we need measured responses, which are not only dimensions and mechanical properties, but also the surface quality from order to order. We are now capable to compare the impact of different press parameters and die designs to maximize surface quality and minimize the surface quality related scrap. But next to this continuous improvement potential, CYRUS provides us with an intelligent alarm system warning the press operator immediately about the loss of quality, like f.e. Tearing, Blisters or Pick-ups. So, the decisions are taken faster at the press. Due to the use of a camera underneath the initial table our press operators are informed about any defect they hardly can detect by their eyes in a second. We are very happy with the CYRUS quality of detection and we do not want to miss this system anymore.”

Dr. Raphael Mertens

Extrusion Process Manager Hydro Nenzing

MashIt